PELLET MILLS

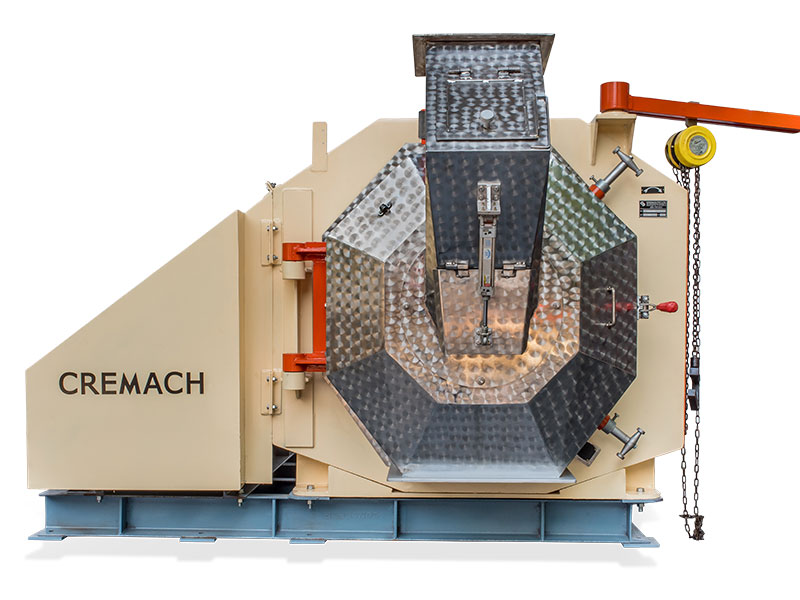

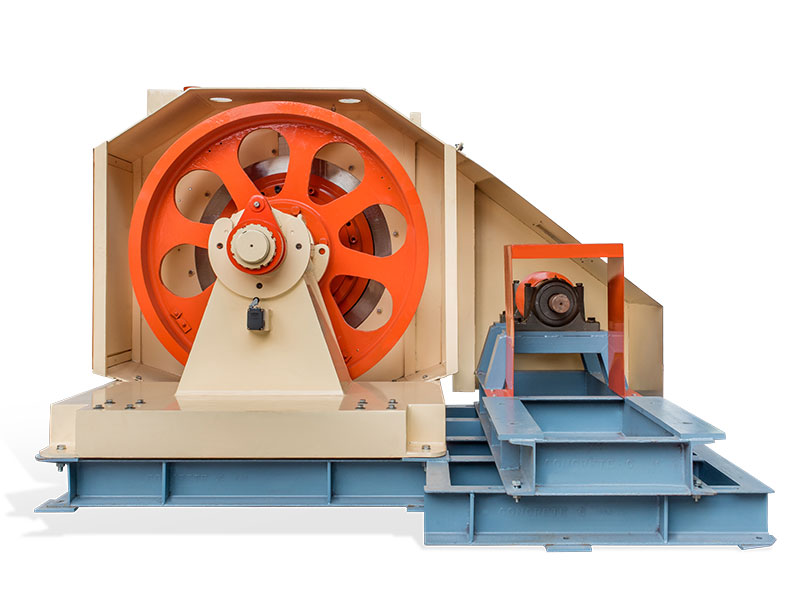

Cremach's Pellet Mill is a vital component in feed plants, producing customer-specific pellets of 2-10mm sizes. It utilizes a vertical type design with a "V" belt drive, available in capacities from 3 to 20 tons per hour.

The mill boasts a solid welded steel frame, ensuring stability and durability. Equipped with a speed-controlled feeder, steam conditioner and retentioner, it achieves superior pelleting. Cremach's Conditioners retain material within the system, maintaining the ideal temperature range of 60°-80°C for high-quality pellets. Constructed from stainless steel, the machine ensures longevity and efficiency.

For convenience, the pellet mill features a servicing hoist for die and press roll changes. Safety devices like shear pins and limit switches protect mechanical components, drive belts and the main drive motor from overloading. Maintenance is facilitated with supplied hand tools, an adjustable torque wrench and a hydraulic press for easy shell removal from press rolls.

-

Automatic Operation

-

Low Operation Cost

-

Uniform Product Quality

Features

- Complete auto-operation system that controls the mash feed rate, steam temperature and molasses (in the case of cattle feed), reducing dependency on operators. The auto-operation pelleting station ensures uniform product quality and near 100% machine operation efficiency.

- The Pellet Mill is designed to minimize vibrations and features shock absorbers to reduce the transmission of vibrations to the steel structure.

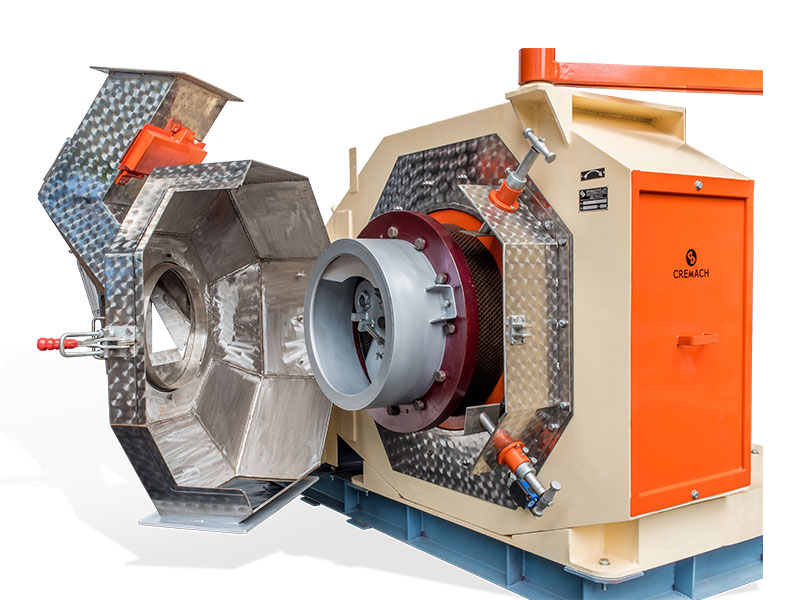

- The central shaft assembly is heavy and robust, ensuring a long lifespan and low maintenance operation. Quick-release knife assemblies allow for easy regulation of pellet length and specially designed scrapers aid in this process.

- The Pellet Mill boasts a large extrusion area for higher capacity and is equipped with a twin-shaft paddle type conditioner with adjustable paddles. The conditioner provides longer retention time and uniform steam injection, further enhancing pellet quality.

- Auto Lubrication facility to grease the bearings on the Pellet Mill while in operation.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.